Print

Back

Print

Back

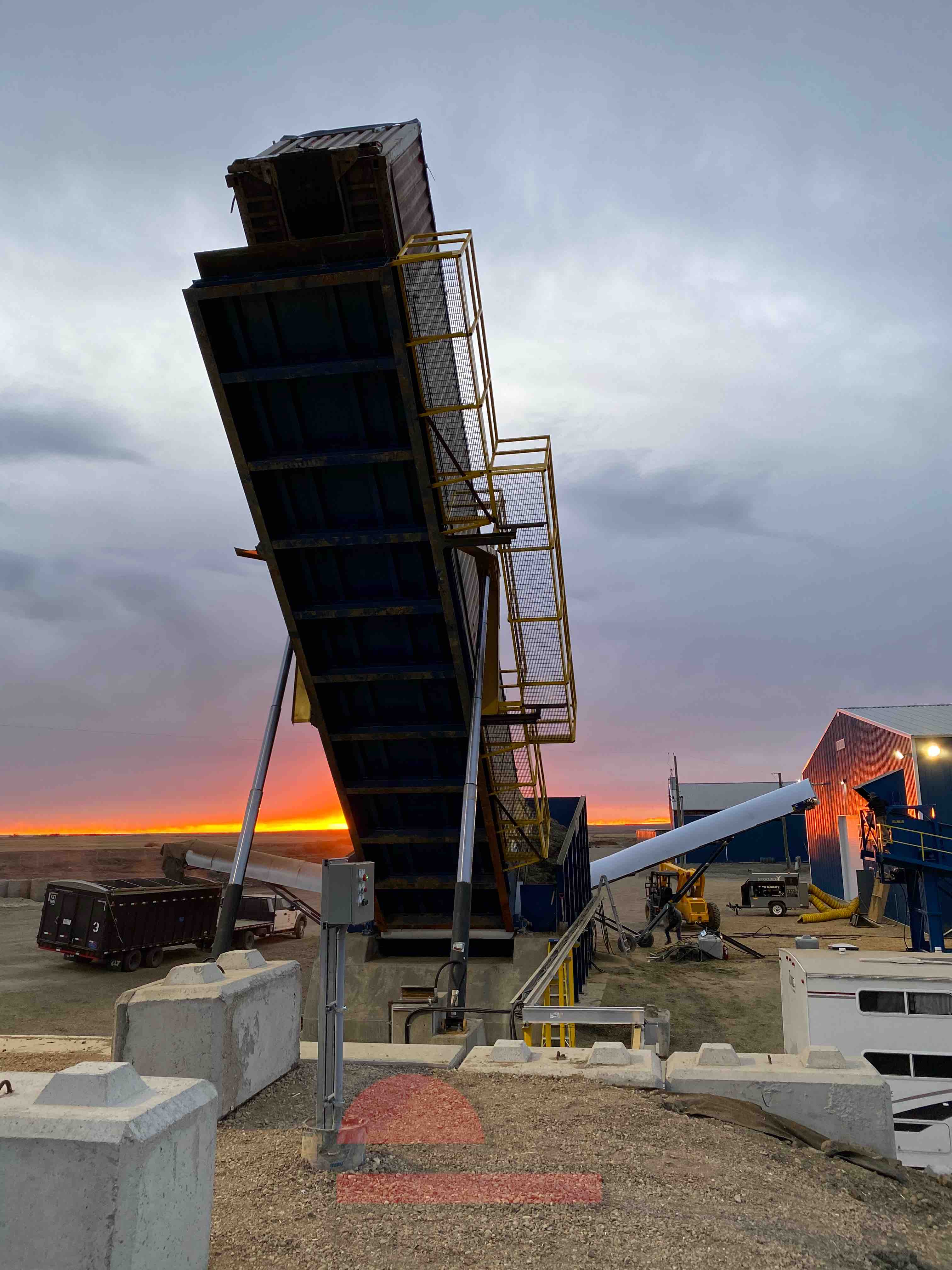

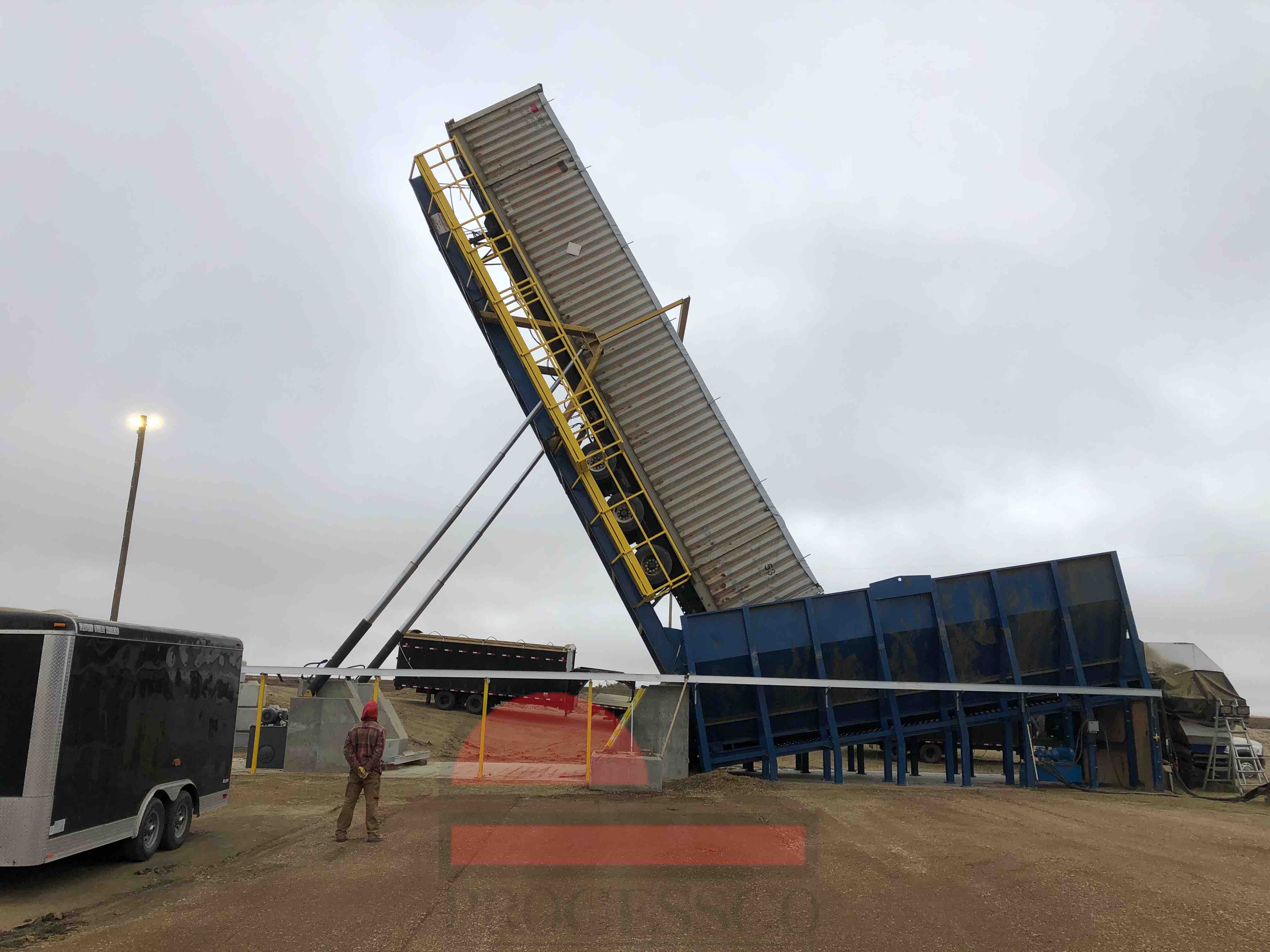

Stationary Chip Dumper Unloads 53’ Trailers and Receiving Hopper consisteing of:

- Maximum tilt angle, “A-frame” type, hydraulically operated.

- Standard pivot back-stop model dumper with 45-ton capacity.

- Dumper has Safety Hoop and Safety chain tie down.

- (2) telescoping cylinders.

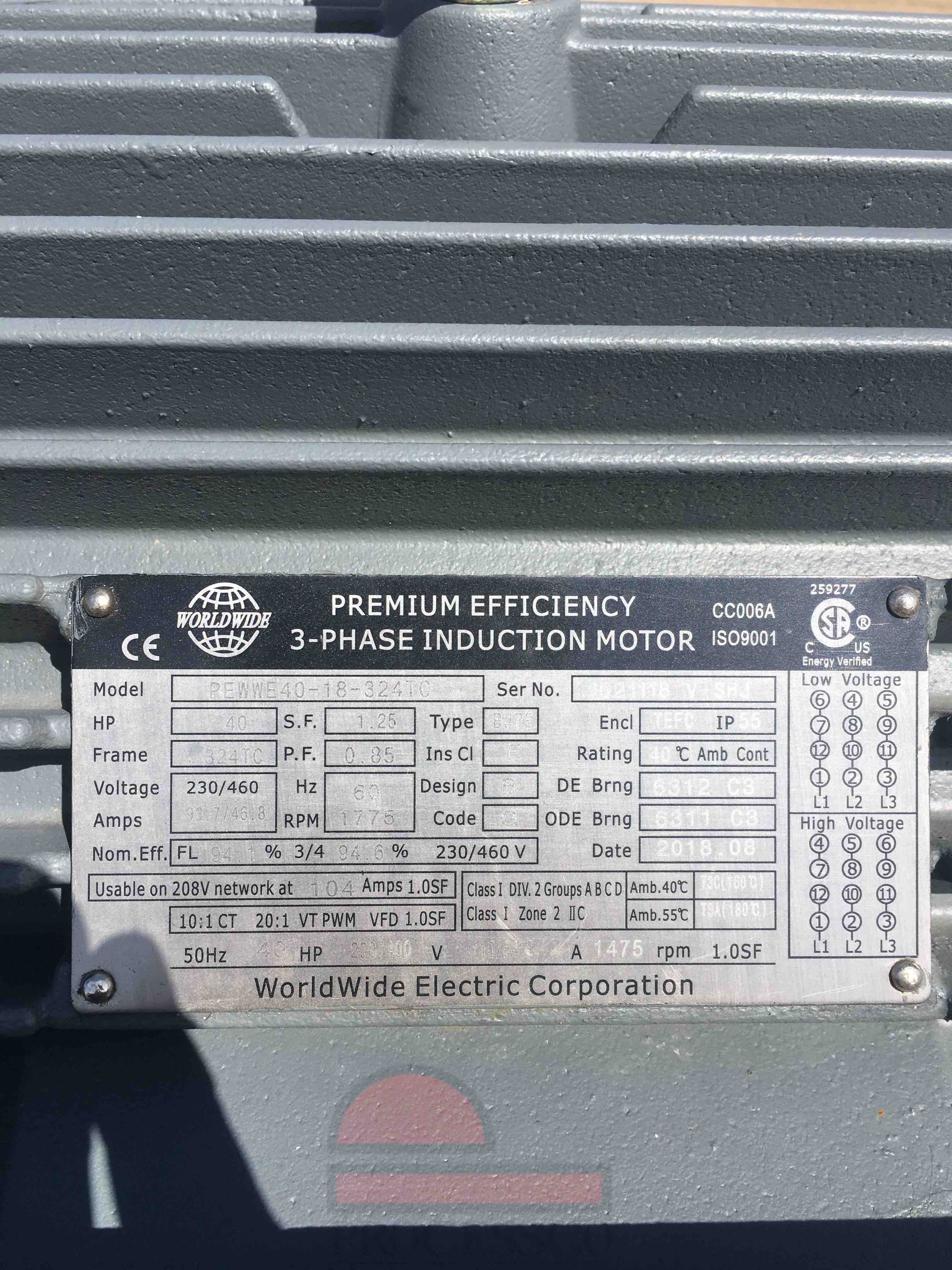

- 40 HP - 480V, hydraulic pumping unit (250 gallon).

- Foundation elevation pier drawings, for raised elevation.

- Dumper.

- Options.

- Oil Tank Heater.

Above Grade Receiving Hopper

- American International 5,000 cu/ft live bottom receiving hopper designed for saw dust and

wood chips.

- 200 tons per hour average discharge wood product @ approximately 10-18 lb. cu/ft

(material size approx. <1”, 2” max).

- 18’ wide top hopper, sides designed with ¼” plate, hopper legs designed

rom 6” I beam, Manual Adjustable Discharge Gate.

- Conveyor incline is approx. 15 degrees.

- Single head drum, live-bottom conveyor

- Six (6) stands of WDH-110 chain and AR guide bars.

- Chains are staggered and mounted on close centers producing a live bottom

that helps provide an even flow, upper deck designed with A-36 3/8” plate with

1/4” AR plate covering. Lower deck designed with ¼” AR plate.

- Drive sprockets are case hardened steel and attached to 14” head drum rollers.

- Chain take-up design adjustable.

- Incude a VFD controlling the Hopper Speed and Direction from.

- Including both the chain Drive Motor and oil Pump Motor.

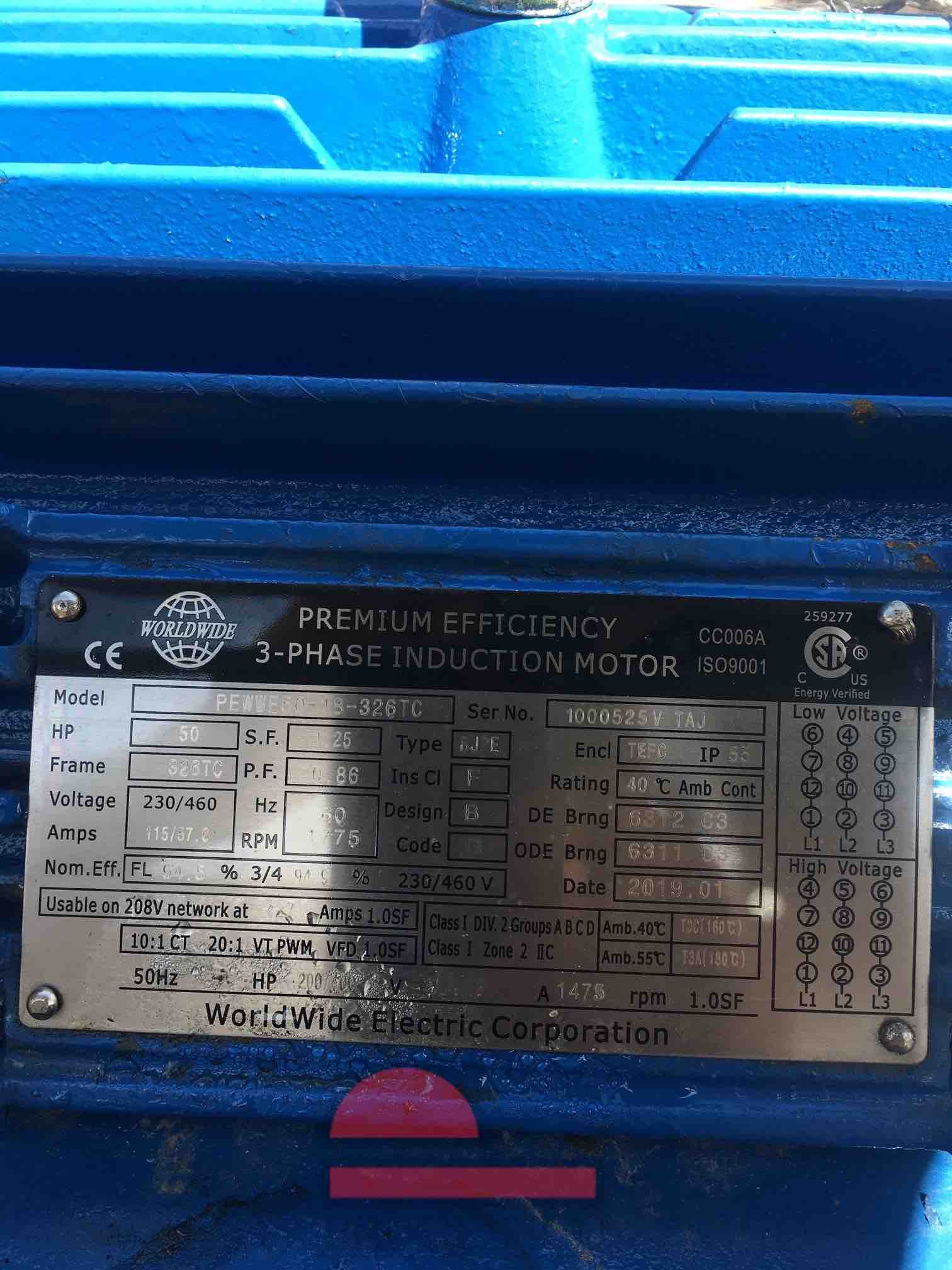

- Planetary gear reducer with direct coupled 50 HP 1800 RPM motor.

- SSPC-SP-6 Mechanical surface prep, one (1) coat primer & one (1) coat high

solids industrial enamel (wear surfaces receive primer coat only).

- Manually adjustable gate discharge.

- Electrical are all 480V.

NOTE:

- Sold "As is- Where is".

- Average Delivery:175 tons per hour estimated at 75% at 18-25 pcf wood chips-225TPH max.