Please note that all Equipment descriptions, photos and documentations on this site supplied to us by the Owner of the equipment are to be used as a guideline only.

A visit inspection will confirm the condition.

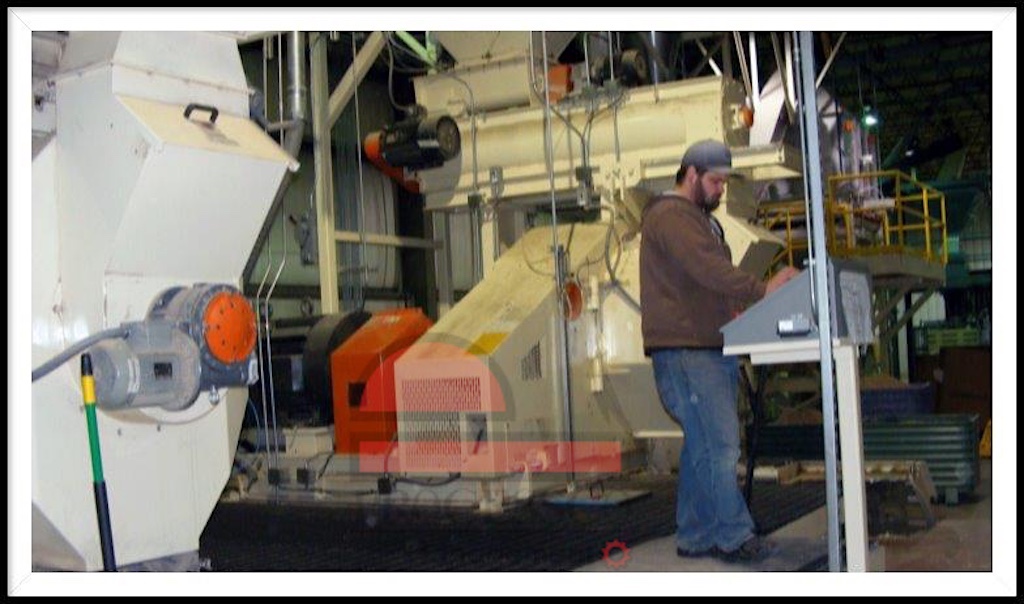

6.5 Ton/hrs - Complete Wood Pellet Plant

6.5 Ton/Hrs - Complete Wood Pellet Plant include:

- Conveyors.

- Screening.

- Magnetic Separation.

- 8 X 36 M-E-C 836-T Wood Chip Dryer System.

- (5) Hammer Mills.

- (2) La Meccanica Pellet Mills Model CLM800P spec to produce 3.5 to 4.0 tons/Hrs each.

- Die type, Lamec 800. 150/285 (46.5 dm 2 )

- Screw feeder C245 (vari-speed drive excluded).

- Conditioner M500 2630 (excluded motor drive).

- Bloc press CLM 800 P including 1 die and 2-roll assemblies.

- Motor 400 HP- 900 RPM not included.

- Force feeder

- Manual winch (hoist)

- Automatic lubrication system for pellet mill

- Pump

- Distributor

- Rotative connection for lubrication system

- Electrical panel for lubrication pump.

- Milpro Counterflow Cooler 8 tons per hour Storage.

- Bin (Silo) 500 cubic foot capacity

- Bagging Line. Nova Bagging Line with Kawasaki stacker. 12 bags per minute.

* The system must be capable of packaging 480 pounds, 12 (40 pounds) bags of wood pellets per minute.

* The system must be capable of supporting multiple bag sizes.”

- Kawasaki ZZD130S Robot Palletizer including inline-turner-flattener conveyor system.

- Wulftec SML-150 Semi-Automatic Stretch Wrapper

NOTE:

- Unit sold "As is - Where is".

- See the Equipment performance specification below.

Our Videos