Please note that all Equipment descriptions, photos and documentations on this site supplied to us by the Owner of the equipment are to be used as a guideline only.

A visit inspection will confirm the condition.

4 Ton/hrs complete Wood Pellet Plant.

4 Ton/hrs Wood Pellet Plant with Dryer System.

Sawdust Raw material receiving Line:

- 247 Cu.Ft Intake Hopper.

- 3 HP Screw Conveyor X 8'0" Long - Cap 423 Cu.Ft/hr. (SDLSS25).

- 5 HP x 25'0" High Bucket Elevator - Cap 5-6 Ft./s. (SDDTG36/18).

- 45 Cu.Ft Grinding Bin.

- Rotary Paddle Upper Level Indicator.

- 1.5 HP Impeller Feeder - cap 5 Ton/Hr. (SDRF5).

- 200 HP Hammer Mill - (SDHM6).

- Auto Load Controller.

- 47.2 " Cyclone. (55-1200).

- 5 HP Rotary Air Lock (SDGFY7).

- 75 HP Hi Pressure Blower (9-26-6.3C).

- Air Piping.

Rotary Drum Dryer complete System:

- 7 Ft Dia. x 40 Ft Long Single Pass Rotary Drum Dryer (HG-2200x12000).

- Dual Cyclones System with Airlocks.

- Connecting Piping.

- Fan 100 HP x 1150 RPM.

- Gaz/BioMass Burner with pipe & Hardware connection.

- Collecting Conveyers with Motors & Drives.

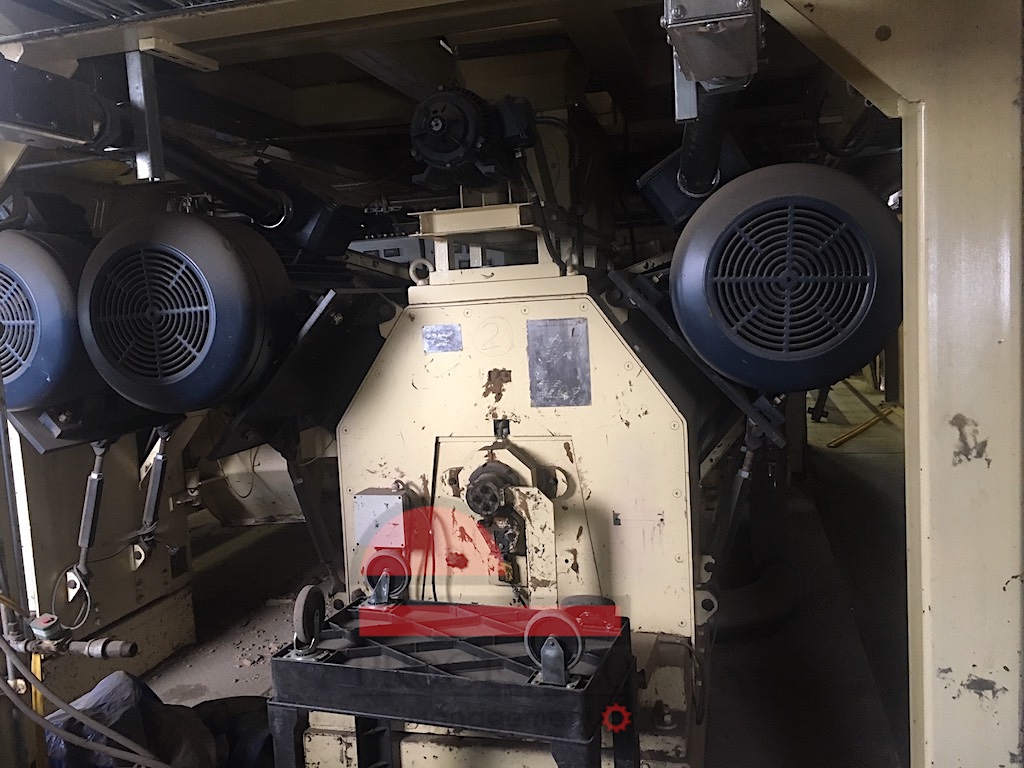

(2) Two Pelleting Systems having each:

- Pellet Mill Feeder Bin - Cap 81 Cu. Ft.

- Rotary Paddle Upper/Lower level Indicator.

- 10 HP Live Bottom Bin (SDTD150).

- 3 HP Screw Feeder cap 3 Ton/Hr. (For SDPM520).

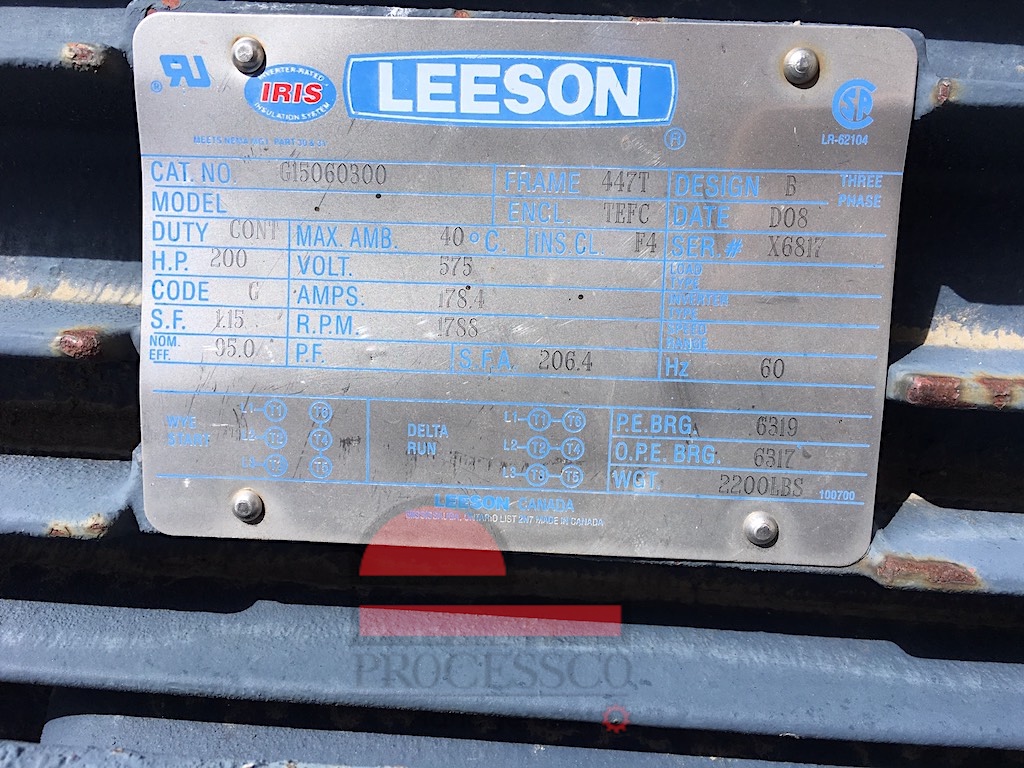

- Two 200 HP (2x 100HP/Mill) - V-Belt Pellet Mill - cap 2 Ton/Hr. @6mm. Pellet size (SDPM520-80).

- Twin Motor V-Belt Pellet Mill having 20.5" ID Die x 2 Rolls assembly.

- Automatic Greasing System.

- 27.5 " Dia. Cyclone.

- 2 HP Rotary Airlock (SDGFY20)

- 20 HP Hi Pressure Blower (9-19-5A).

- With complete Air Piping.

- Counterflow Cooler x 2 HP - cap 3 T/Hr. (SDCC5A).

- 28.6"Dia. SS Cyclone.

- Rotary Airlock x 2 HP (SDGFY20).

- 15 HP Hi Pressure Blower (9-19-5A).

- SS Piping.

- 47.3" Dia. SS Cyclone (50-1200).

- 15 HP Blower (4-72-5C).

- Rotary Air Lock x 2 HP (SDGFY7).

- SS Air Piping for Cooler.

- Transition Hopper.

- Screw Feeder x 2 HP - cap 1 Ton/Hr (SDWLL16).

- Two Way Pneumatic Gate (SDSTQ25X25).

- Screener single Deck Sprout Model 2.5 x 6 Roto-Shaker x 1 HP - Cap 1-3 Ton/Hr. (SDVS 0.4).

- Cable suspending Assembly for above.

Bagging System: SOLD

- 31 Cu.Ft. Packing Hopper.

- Rotary Paddles Upper/Lower Level Indicator.

- Bagging Scale - 50kg/bag (LCS-520).

- 2.5 HP Sewer and Belt Conveyor.

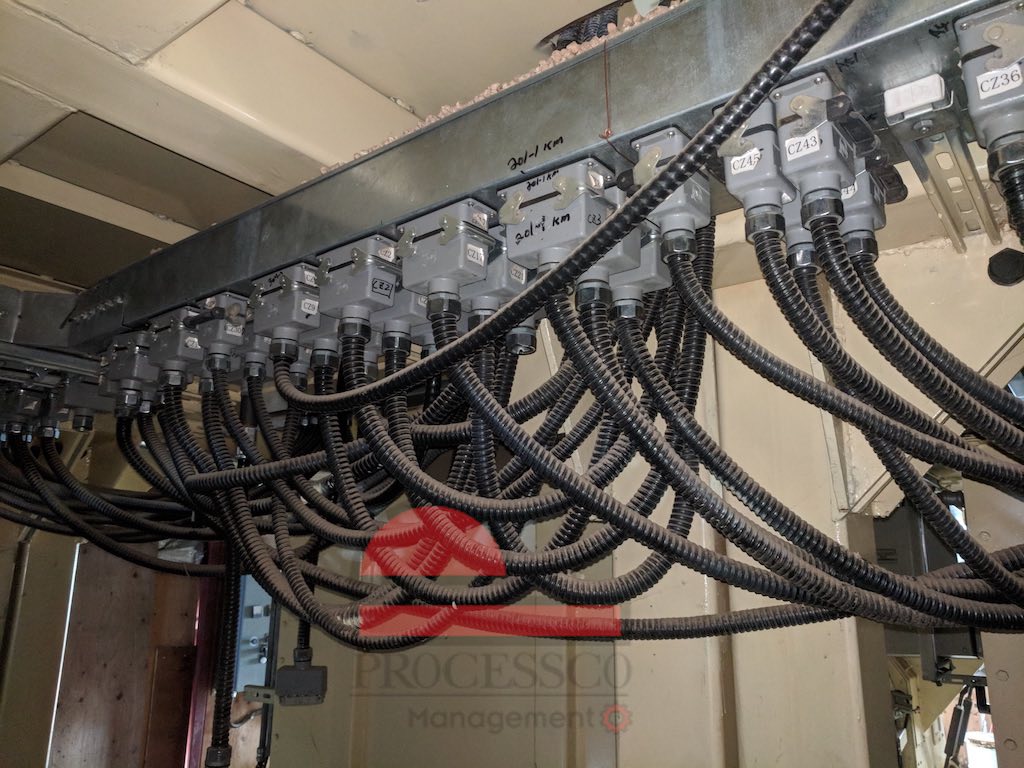

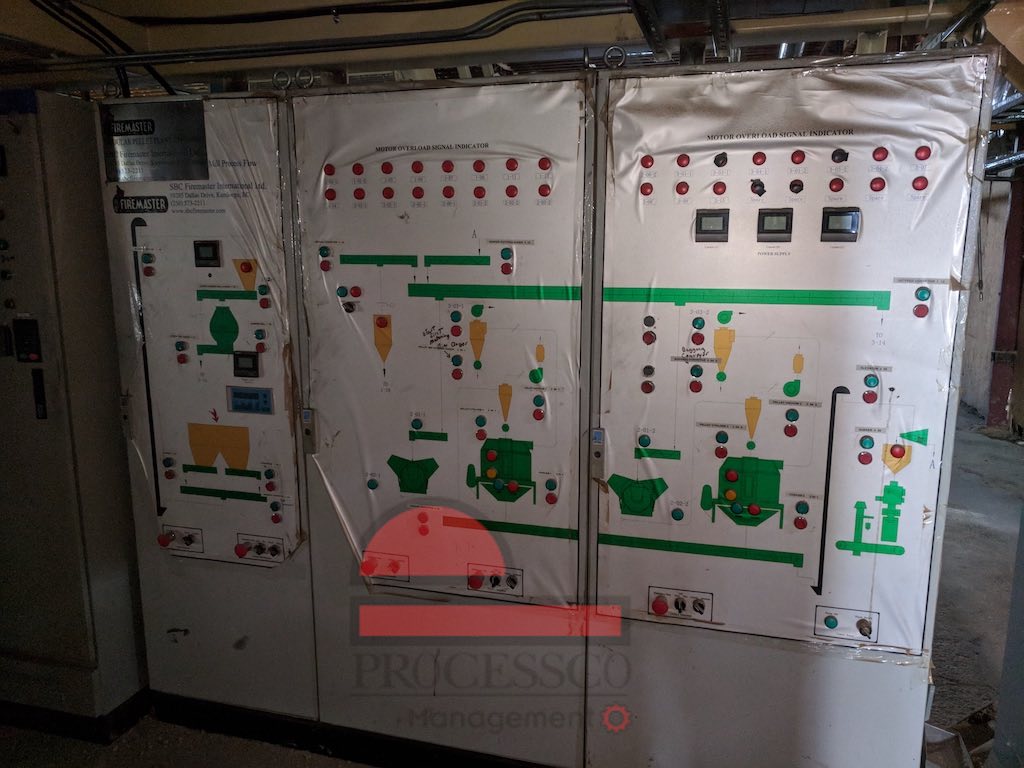

Electrical Componence:

- Electrical Control Panel - 575/3/60.

- All Motors and Reducers.

- All Electric Swiches & 3 Phase Starters.

Spare Parts:

- Available as extra (see list in documents below).

NOTE:

- Plant purchased new and ran for a couple of years.

- Price does not include dismantle.

- Can supply a technician to commission the Plant once re-assemble.

Our Videos