Print

Back

Print

Back

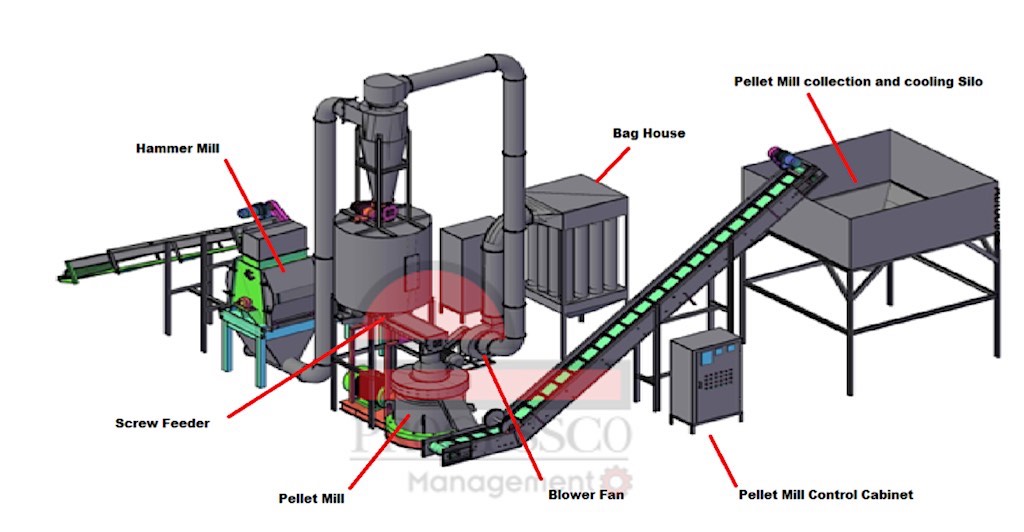

3.5 to 5 Tons/hrs complete Wood Pellet Plant revised list consisting of:

1- Pellet Mill KESIR Model BFR 220:

New never used 300 HP Horizontal Ring Die Pellet Mill. 24/7 operable high torque Pellet mill with Bearing free long-life Mill head and Rollers. Reversible 1/4" Pellet Die for long use. We have 1 set of dies currently installed and they have not been used. The die size is 6mm currently. Production range of 3.5 to 5.5 tonnes per hour depending on biomass type. 225KW total motors.

1 -Hammer Mill:

480VAC - 125 HP (90 kW) Hammer Mill with 7/16” screens.

1- Shredder (110kW) with chain conveyor and feed rollers (USED).

110kW Shredder / chipper with hopper and chain conveyor. Unit equipped with feed rollers and adjustable blades. Hydraulic power unit available for lifting and accessing rollers and blades.

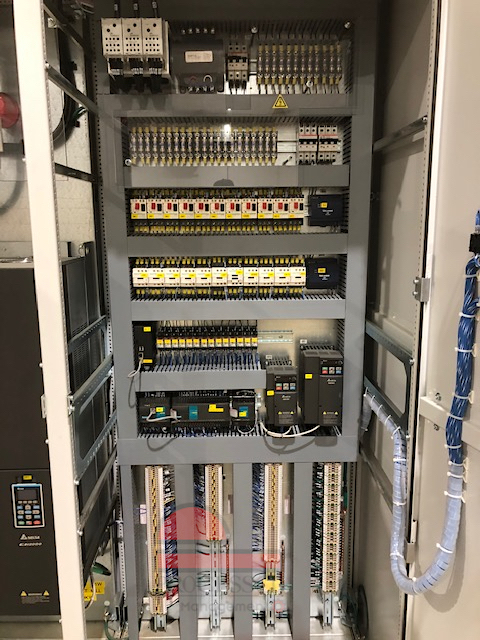

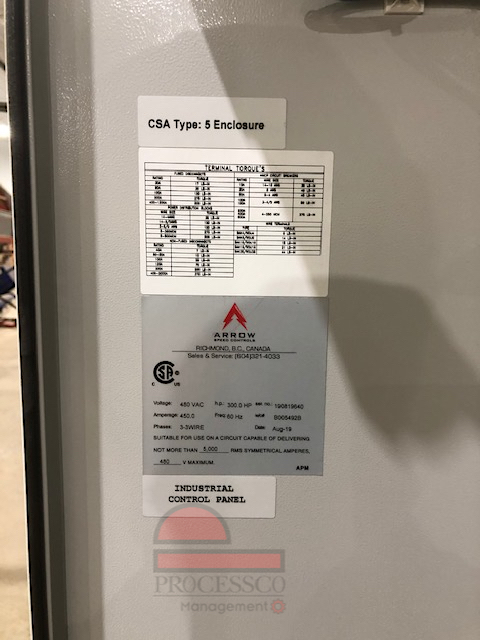

*1- UL/CSA Electrical Control Panel for Pellet Mill Plant:

Industrial Electrical Control Panel by Arrow Speed Controls. 480VAC 3 Phases. Wiring schematics available. Panel designed to control the following Items:

1-UL/CSA Electrical Control Panel for Shredder and Hammer Mill:

Industrial Electrical Control Panel by Arrow Speed Controls. 480VAC 3 Phases. Wiring schematics available. Panel designed to control the following

1- Pellet Mill Screw Feeder:

Silo and Variable Speed Screw for prefeeding milled product to Pellet Mill.

1- Pellet Mill Feeding Bin:

Surge Bin for collecting milled feedstock prior to transport to Screw Feeder and Silo. Inlet Cyclone, Feed Auger and discharge Airlock/Tourniquet.

1- Pellet Mill Cooler Model BFR 220:

Silo for collecting and cooling pellets.

1- Transport Fan FJ15:

Blower Fan for transporting material from hammer mill to collection silo 15kW.

1- Misc support Components:

Misc. Interconnect Piping and Sock type Baghouse.

*2- Pulse Dust Collector 3KW, 7.5KW. Two baghouses (USED)

Each unit comes with filter socks and some spares. Unit 1 3.5kW, Unit 2 7.5kW Both units include standalone separate and configurable pulsing control system

*5- Conveyors assorted lengths with 3kW Drive (SOME USED)

Assorted modular interconnect conveyors for product transport. 3 incline designs and 2 straight. 3kW 480VAC drive

NOTE:

- Sold "As Is - Where is".

- All Controls & Motors are 480VAC 3 Phase.

- All Equipment is New, some are still crated, never installed. Any used items have been noted in above descriptions.

- All Service & Installation Manuals are included.

- Some Equipment Drawing included.

- New Items with * as been added after March 12-2023.